1. Chii chinonzi welded silinda?Iyo dhiramu inosungirirwa yakananga kumavharo ekupedzisira uye zviteshi zvinosungirirwa kune dhiramu.Iyo yekumberi tsvimbo gland inowanzo bhaudhiwa kana kuiswa muhumburumbira, iyo inobvumira kuti piston tsvimbo yekubatanidza uye zvisimbiso zvetsvimbo zvibviswe kushanda.Welded hydraulic cylinders ane akati wandei mabhenefiti pamusoro pemasilinda etsvimbo.Kunyange zvazvo masilinda ekusungira angave akachipa kugadzira, anowanzoonekwa se "kubva pasherufu" zvinhu uye ane mashoma sarudzo maererano nekugadziriswa.Izvo zvakare hazvina kusimba zvakanyanya kupfuura welded cylinders.Welded body cylinders anogona kuve akajairwa-engineered kune chaiwo maapplication.Silinda dzakasungirirwa dzinewo zvisimbiso zvepamusoro, izvo zvinogona kubatsira kuwedzera hupenyu hwehumburumbira uye inogona kubatsira kana silinda ichashandiswa munzvimbo dzinosanganisira kusvibiswa uye mamiriro ekunze.Aesthetically, welded body cylinders ane yakaderera profiles pane tie rod silinda uye anogona kuvandudza kutaridzika kwemidziyo iyo inoshandiswa pairi.Sezvo iwo akatetepa pane yavo tie tsvimbo yakaenzana, welded hydraulic cylinders anoshanda nemazvo mumashandisirwo ayo nzvimbo chinhu chinhu.

2. Nzira yekudzora sei welding quality panguva yekugadzirwa kwehuwandu?

Welding Equipment;Gadzirira sampu yewelding zvakanyatsoenderana neyakafanotemerwa maitiro ezvinodiwa: Preheating, welding, kuchengetedza kupisa, uye kugadzirira welding sampu.Uye kugadzira welding process kadhi kuti ipe hwaro hwekushandiswa kweiyo welding;Welding zvinhu, welding waya uye welding gasi zvinhu yunifomu, kugadzikana kuita, yakakwirira gasi kuchena, uye reshiyo yakarurama;Welding munhu, anoda kuva welder's certificate;Welding bvunzo, senge weld bead simba rekuyedza uye ultrasonic bvunzo yekutarisa welding mhando.

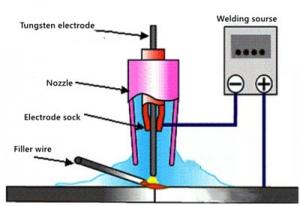

3. Gas shielded welding inogona kukamurwa kuva inert gas shielded welding (TIG welding), inoshanda gasi shielded welding (MAG welding) .Gas shielded welding (TIG neMIG welding).Zviripachena, argon inonyanya kushandiswa nekuda kwemutengo wakachipa, saka inert gasi yakadzivirirwa simbi arc welding inozivikanwawo se argon arc welding.Tungsten inert gasi welding ndeye welding process umo tungsten kana tungsten alloy inoshandiswa se electrode zvinhu, uye arc inogadzirwa pakati pe electrode uye base zvinhu inoshandiswa kunyungudutsa base zvinhu uye kuzadza waya pasi pekuchengetedzwa kweinert gasi. .

TIG, inozivikanwawo seGas Arc Welding (GTAW), inzira yekugadzira Arc pakati peTungsten electrode uye base simbi pasi inert gasi kudzivirira kuitira kuti hwaro simbi uye welding waya zvinhu zvinyunguduke uye wobva wabatanidzwa.Inosanganisira DC TIG welding uye AC TIG welding.

DC TIG welding inotora DC arc welding simba sosi sesimba remagetsi remagetsi, rine simba rakanyanyisa uye rakanaka base zvinhu.Inonyanya kushandiswa kugadzira simbi isina tsvina, titanium, mhangura uye mhangura alloy.Iyo welding simba sosi ye AC TIG welding inobva ku AC arc, uye anode uye cathode ye base material yakachinja.EP polarity electrode overheating inogona kubvisa base material surface oxide layer, inonyanya kushandiswa aluminium, magnesium, uye imwe alloy welding.

Apo TIG (GTAW) welding operation, welder inogona kuva pfuti yemoto mune rumwe ruoko uye welding wire muruoko, inokodzera diki-scale kushanda uye kugadzirisa manual welding.TIG inogona kugadzirwa dzinenge dzese simbi dzemaindasitiri, inopa yakanaka welding chimiro, shoma slag uye huruva inogona kushandiswa zvakanyanya mutete uye gobvu simbi ndiro.

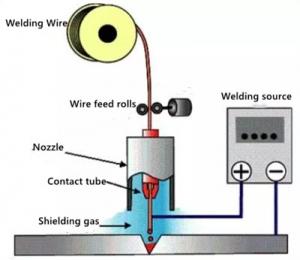

MAG (Metal Active Gas) Welding inoshandisa CO₂ kana musanganiswa weargon uye CO₂ kana oksijeni (A Active Gas).Welding yeCO₂ gasi dzimwe nguva inonzi CO₂ arc welding.MIG neMAM welding midziyo yakafanana pakuti inogona kudyiswa kunze kwetochi neatomatiki waya yekudyisa uye inokodzera otomatiki welding, tisingataure welding yemawoko.Musiyano mukuru pakati pawo uri mugasi rinodzivirira, iro rekare rinowanzo chengetedzwa negasi rakachena reArgon, rakakodzera simbi isina-ferrous;MAG welding inonyanya kushandisa CO₂ gasi, kana argon yakasanganiswa CO₂ gasi rinoshanda, rinova Ar+2%O₂ kana Ar+5%CO₂, yakakodzera simbi yakasimba uye yakakwirira alloy simbi.Kuti uvandudze mashandiro eCO₂welding, CO₂+Ar kana CO₂+Ar+O₂ yakasanganiswa gasi kana flux-cored waya inogona kushandiswa zvakare.MAG welding inoratidzirwa nekumhanya kwayo kumhanyisa, yakakwira arc initiation performance, yakadzika dziva, yakakwirira deposition kunyatsoita, kutaridzika kwakanaka, mashandiro ari nyore, akakodzera kukwirira-kumhanya pulse MIG (GMAW) welding.

Fast yakazvipira kuR&D uye kugadzira kwehydraulic cylindersuye hydraulic systems, kushandira vatengi uye kupa vashandi hupenyu huri nani.Parizvino, takabatsira zviuru zvevatengi pasi rese-inopa hunyanzvi mune hydraulic silinda uye sisitimu dhizaini ine makwikwi mabhenefiti.

Nguva yekutumira: Sep-16-2022